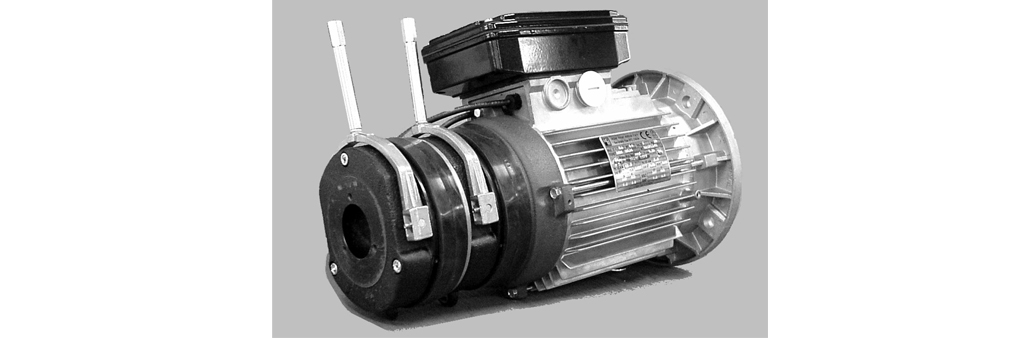

Σειρά BMBM με διπλό φρένο

BMBM series consist of three phase asynchronous brake motors with twin brakes working independently one of each other, with power range from 1/2 up to 40 HP.

BMBM series main feature is a very high reliability for those lifting applications where there are high demands of safety and quiet. For these reasons BMBM series motors are particularly suitable to be used on TV-cine studios and theatre’s stages.

The motor brakes in case of power supply failure. The braking action is obtained without axial shaft sliding and it provides an equal braking torque in both running directions. The brake components and assembly are designed with special features to be particularly silent during the stops, granting the high ratings of EN81 (German Std).

The manual brake release is made up of two levers (one for each brake) so to avoid unwanted starts. It’s possible to release the brake using just one hand. The two brakes are supplied through independent rectifiers which are positioned in the terminal box. Rectifiers are provided with an over-voltage protection device and with an EMC filter.

BMBM series motors are suitable for inverter use; On request it’s possible to have the motor with a built-in encoder or to have the motor ready for the encoder to be mounted.

The brake disks friction material is asbestos free and the brake lining has an high friction factor and a long-lasting. The winding insulation class is F. Class H is available upon request. Motor construction type is Totally Enclosed Not Ventilated with IP 54 protection degree (IP 55 and external cooling are available upon request).

BMBM series motors, working on intermittent duty, tolerate an heavy overloads. On request it’s possible to provide motors with thermo-protection devices. Frame is made of die cast, light metal on motors up to 10 HP frame size and of cast iron on motors up to 40 HP. Feet are integrated in the frame to make the whole motor more solid since the applications in which these motors are used are critical. Plates and flanges are made of aluminium up to 2 HP and of cast iron on higher frames.